So I'm going to attempt writing my first tutorial - let's start with a simple project for a beginner at silversmithing. A small charm like this is a great first project, being versitile to wear - on a charm bracelet, necklace, or turn into earrings - and you don't need a lot of equipment to make this. I opted for a geometric diamond design which is a good oportunity to practice accurate piercing, but other geometric designs will work just as well (see my post on geometric designs for inspiration).

Materials and equipment needed:

15mm x 15mm of 0.5mm width sterling silver sheet2 x 0.5mm heavy sterling silver jump rings

A silver chain, if wearing as a pendant - I use a 18' trace chain

Piercing saw and 2/0 blade

Needle files

Drill and drillbit (I used 0.8mm)

Piece of wood

Optional: Soldering equipment (torch, soldering block, flux, hard solder, pickle)

Barrelling machine or pendant drill with radial discs

Chain nose pliers

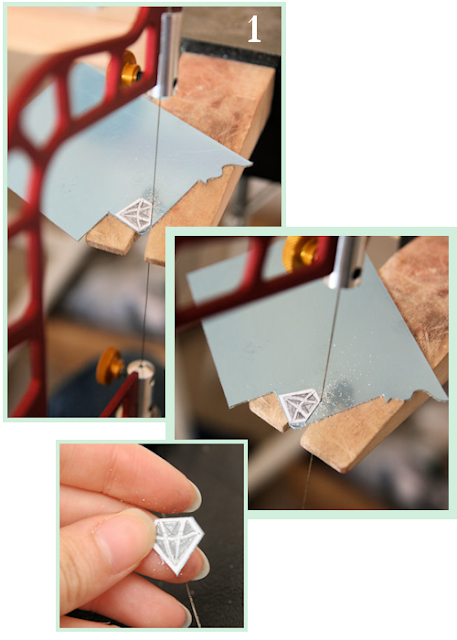

Step 1 - Pierce out your design

On paper, draw out your design in pencil, cut it out, and use double-sided tape to stick it straight onto the silver sheet. Insert the saw blade into the piercing saw and make sure there is plenty of tension in the blade so that it 'sings' when you brush it with your thumb (if you're using a cheaper saw, push the top of the saw frame into the bench whilst tightening the bolt). Then cut around the outside of the design. Make sure not to force the blade forward too hard, but concentrate on the up and down motion. When you get to a corner, keep the blade moving up and down without going forward, whilst slowly turning the saw frame around the corner.Step 2 - File around the edges

Once you have your shape cut out, use a flat needle file to go around the edges and file away the saw marks. You should end up with nice straight edges which don't have any visible scratches. Round off any sharp corners with the file.Step 3 - Drill into each cut-out area

Place your design onto a piece of scrap wood (to save your workbench or table) and carefully drill a single hole into the centre of each cut-out area.

Place your design onto a piece of scrap wood (to save your workbench or table) and carefully drill a single hole into the centre of each cut-out area.Step 4 - Pierce the cut-out areas

Carefully thread the saw blade through the drilled hole, then re-tighten the bolt and check the tension. Then pierce out each cut-out area. For really tight corners, go into it from one side, then move the blade back to the drilled hole, and pierce into the corner from the other side.Step 5 - File each cut-out area

Peel off the design and protective film from the silver.

Peel off the design and protective film from the silver. File carefully each cut-out area, using a triagular or barrette file (which only files on one side, the back is blank and won't cause accidental scratches).

Step 6 - Solder a jump ring bail to the charm

This step is optional - if you don't have soldering equipment, you can simply use pliers to open a jump ring and thread it through one of the cut-out holes near the top, then use the pliers to close it again.For a more complete piece though, line up the silver design on a soldering block to a closed jump ring (with the join of the ring next to the edge of the design). Brush a drop of flux onto the point where the ring and charm meet, then use a very small piece of hard silver solder and position it onto the join.

Turn on the torch and run the flame all over the charm piece (don't concentrate the flame on the jump ring, as it's smaller and may melt). The aim is to get everything to the same temperature. When the piece starts glowing red, focus on the jump ring and the piece of solder, until it flows, then immediately remove the flame. The solder should fully cover the join between the ring and the charm. Wait for a few seconds, then quench the charm in a pot of water, using tweezers.

Step 7 - Pickle the charm

If you soldered in the step above, now pickle the charm. An old slow cooker is a good option for keeping pickle warm. Or you can use my cheat option (until I buy a slow cooker) - I use safety pickle and make a small amount of pickle in a plastic pot, placed in a saucepan half-filled with water, on the lowest hob setting. Leave your charm in the pickle until it turns white (see picture 7, above).Final step - Polish the charm

If you have a barrelling machine, put the charm into the barrel (half-filled with water, a few drops of barrelling fluid and with a good quantity of mixed steel shot) and turn the machine on for at least an hour.If you are using a pendant motor or Dremel, use a radial disc set to polish the charm - use yellow first, then blue, then finally green.

Finally, thread the other jump ring through your soldered ring, so that you can now attach the charm onto a chain or charm bracelet - and that's it! A simple project which you can try to make an eye-catching piece of jewellery.

|

| The final charm - wear it as a necklace or on a bracelet |

- Instead of cutting the shape outline first, try what James suggests and pierce the inside first - "Piercing the inner holes first means that you have plenty of metal to hold while manipulating the sheet, both for piercing and also if you need to do any filing on the inner pierced holes, I would pierce out the outer shape last"

- Try using a finer saw blade - 4/0 - for cutting 0.5mm sheet

- When piercing a flat piece, try cutting at a right angle to the photos shown above - "try piercing across the bench peg,at right angles to your face, if you are right handed piercing from right to left across the bench peg V slot. I was taught that it is better to see where the blade is going, rather than where it has been."

Excellent tutorial, I'm really hoping you will do more of these tutorials as so clear to understand and the photos are great to follow. Thank you!

ReplyDelete